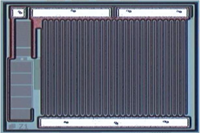

Dummy Bare Die are processed using Silicon (Si) material with either patterned or mirrored mechanical top finish.

Step 1 - Provide Dummy Bare Die Mechanical Specification

Please select your Die requirements:

- Die Size X - mm, µm or mils (thousands of an inch)

- Die Size Y - mm, µm or mils (thousands of an inch)

- Die Size Thickness (Z) - mm, µm or mils (thousands of an inch)

- Topside Pad Metal Type - For example Aluminum (Al) or Gold (Au)

- Backside Metal Type - For example Silver alloy (Ag) or Gold (Au) or No backside metal - Bare Silcon (Si)

- Dimensional Tolerance ± - To assist availability and shorten delivery times

- Topside finish - Patterned or Mirrored (patterned die are more likely to be stocked)

- If patterned finish - How many wire bondable pads preferred? And preferred bond pad size?

Step 2 - Choose Supply Format

Please select preferred die supply format:

Option 1 - Dummy Bare Die in 2" Conductive ESD Waffle Tray/ Waffle Pack

(Static is a factor when loading and offloading die using die handling equipment)

Pros

- Suitable for low quantity

- Ease of handling and long term storage

- We carry a large range of 2" Waffle Packs / Waffle Trays in stock which may accomodate most die sizes

Cons

- Unusual die sizes may require a customized tray which must be tooled at higher cost and lead-time

- Not suitable for automated assembly calibration or automated setups which are not tooled to accept waffle pack

Option 2 - Dummy Bare Die in 4" Conductive ESD Waffle Tray/ Waffle Pack

(Static is a factor when loading and offloading die using die handling equipment)

Pros

- Suitable for low quantity

- Ease of handling and long term storage

Cons

- Unusual die sizes may require a customized tray which must be tooled at higher cost and lead-time

- Not suitable for automated assembly calibration or automated setups which are not tooled to accept waffle pack

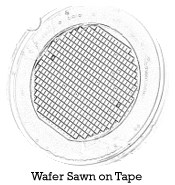

Option 3 - Dummy Bare Die as Diced Wafer on Film-Frame

Choice of UV dicing tape (pre-irradiated or non-irradiated) or Blue sticky dicing tape

Our standard is FFP-200 frame other Film-Frame sizes are available on request to suit equipment.

Pros

- Fits many fixtures and tooling for automated die handling

- Mass production format means dummy die process trials better match real production.

Cons

- Tape has a limited shelf-life before all die must all be removed

- Not suitable for long term storage and ad-hoc low qty use

Option 4 - Dummy Bare Die Diced Wafer on Grip-Ring (also known as Hoop-Ring or Expander Ring)

Choice of UV dicing tape (pre-irradiated or non-irradiated) or Blue sticky dicing tape

A range of grip-ring specifications are in stock, non-stocked rings can be ordered in specially

Pros

- Many different ring sizes to match automated die handling equipment

- Easier to modify tooling to suit a ring compared with film-frame

Cons

- Tape has a limited shelf-life before all die must all be removed

- Not suitable for long term storage and ad-hoc low qty use

Step 3 - Choose Qty required and send your enquiry to sales@diedevices.com