1. Storage & Ease of access

- Quantity - Your usage is less than the quantity of one wafer

- Storage - Bare die are not recommended to remain on sawn wafer tape for any long period of time. This is because the die backside risks contamination by the tape adhesive over time.

- Schedule - Customer requirement is staged, meaning die need to be stored and made available for production on demand. Alternatively die may be obsolete and require long term storage in a highly reliable format.

- Distribution - Pack-sizes smaller than one wafer are needed for either 3rd party sale / sampling or to be issued to 3rd party assembly contractors.

2. Assembly Equipment

- Assembly equipment does not accept the wafer frame or ring that the wafer has been sawn on.

- Pre-picked bare die may be more efficient in terms of setup time for a high mix low volume production environment

- Some flip-chip assembly equipment doesn't have the option to auto-invert the die meaning the die must be presented the other way up

- Certain products and markets require high levels of visual inspection which may be better performed on pre-picked bare die.

3. Electrical and Temperature selection

- Binning / Grading - Wafer testing produces different electrical grades which must be picked and segregated

- Pairing - Bare die must be picked and stored as pairs for later assembly to achieve close die-to-die matching of electrical characteristics

4. Multi project or Pizza mask wafers

There are multiple die types on the project wafer which must be individually picked, labeled and stored.

Picking Media

Waffle trays - Bare die are typically picked into waffle pack format. Suitable X-Y dimensions must be chosen to prevent rotation of the die and also to leave enough clearance for assembly equipment to access the die. Care should also be given to the choice of pocket depth + suitable lid for the tray to ensure the die can't flip or escape the pocket rim.

Waffle packs are sized in either two inch or four inch formats with array sizes starting from as low as 5 PCS up to 1000 PCS. Two inch trays provide the best availability and range for low to medium quanties, four inch are typically used from medium to high volume. At diedevices.com we carry a wide range of waffle trays and lids with a variety of pocket sizes and depths.

Re-constituted tape frame - Some customers may receive their bare die from the wafer fab on a frame that is not supported by their assembly equipment. In those cases it's possible to pick and place the die from the old tape frame onto a new compatible tape frame.

Re-constituted tape frame with graded die - Where bare die are electrically graded, a customer may wish to segregate them but keep them on the tape frame format for automated assembly. This process is useful for building arrays of known good die with a level of high reliability.

Please visit output formats for more information.

Our process

Die are collected from the tape frame using precision semi-automatic equipment.

Contact with the top surface and the eject force on the backside of the die is carefully controlled using a combination of compressed air and vacuum. This results in minimal die contact and better yield.

Depending on the level of complexity of the die, some visual inspection can be performed on-the-fly.

Die with sensitive top surface features can be collected via a collet pickup from the side.

Our equipment

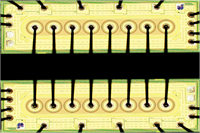

Automated picking of die sizes from 250µmx250µm (10x10 Mils) to 8.4mmx8.4mm (330x330 Mils)

Featuring:

■ 24-hour operation with high-speed throughput =>5K UPH

■ Integrated in-line inspection filtering out visual defects

■ Integrated in-line inspection filtering out ink dot rejects

■ Electronic map picking from all industry recognized data formats

■ In-line rotational adjustment ensuring correct die orientation

■ Minimal contact made to the die top surface.

Automated picking of die sizes from 200µmx200µm (8x8 Mils) to 25mmx25mm (985x985 Mils)

Featuring:

■ Optional die inversion (die flip) for bumped bare die assembly

■ Optional in-line backside visual inspection

■ Optional side collection for topside sensitive bare die

■ Integrated in-line inspection filtering out gross visual defects

■ Integrated in-line inspection filtering out ink dot rejects

■ Electronic map picking from most industry data formats.