There are two principle aspects in getting good bare die product into assembly:

- Electrical test - Please see here for our wafer testing capabilities

- Mechanical quality - Assessed by visual inspection either automated or manual.

The baseline quality for a bare die is that it passes electrical test at wafer level and passes visual inspection after the singulation and handling process into the shipping media.

Pass wafer level test + Pass visual post processing = Bare Die considered good (relative to the electrical test performed).

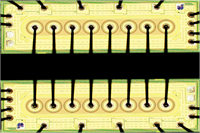

The wafer dicing process is critical in that it is a majority contributor to mechanical quality and by default has an impact on yield, the number of good die per wafer.

What processes are available?

There are several wafer dicing methods in the industry:

- Mechanical dicing (All purpose)

- Scribe & break (Fragile or hard compound & opto)

- Dice before grind (DBG)

- LASER dicing

- Chemical etch dicing.

The most prevalent methods in use today are mechanical wafer dicing and scribe & break. This is largely due to cost effectiveness in terms of throughput, cost of ownership and setup flexibility.

Specialist wafer dicing methods such as LASER and chemical etch are typically useful when:

- Processing volumes exceed the trade-off point between price and throughput versus traditional dicing costs

- The wafer physically requires specialist singulation which these methods can provide

- An extreme highest quality outcome is required where price is no object.

Our in-house process is mechanical wafer dicing

At Die Devices we offer a mechanical wafer dicing service which is suitable for a broad range of semiconductor materials. Where specialist dicing methods are needed we combine working partnerships with equipment makers and our own process knowledge to manage your project.

A diamond embedded blade is used to remove material while process water cools the blade and workpiece

At all times strict control must be made on the cutting water quality which directly impacts cut quality:

- Temperature

- Resistivity

Our wafer dicing service uses a state-of-the-art water processing and recycling plant which delivers unparalleled control. We also automatically inject surfactant to prevent debris adhesion and to inhibit corrosion.

The correct blade choice is then made which takes into account multiple factors:

- The width of the dicing street on the wafer

- The total thickness of the wafer

- The intended dicing process

- Any history or experience with this material.

Where street sizes are small or wafer thickness is high it can be beneficial to thin the wafer before dicing.

There are two types of wafer dicing service available, single pass or step cut, each cut has pros and cons.

We always recommend the process most suitable for the situation.

Single Pass

- Fast throughput

- Suitable for thin wafers

- Suitable for narrow streets.

Step-Cut

- Can reduce topside and backside chipping

- Can reduce effect from blown test pads

- Suitable for thicker wafers

- Requires customer to accept sidewall step.

Tape & Frame Choice

Wafers are mounted onto tape which is held on a Film-Frame. There are multiple tape options and the choice is dependent on the product type and further processing required either at Die Devices or at the customer's facility. For example, ultra-thin die are highly recommended to be diced on UV tape.

The standard frame we use is the Disco FFP-200 frame, other output frames such as Ring-Frame are possible subject to setup tooling and volume levels.

Optimisation

First time wafer dicing always involves a trial cut to set key machine variables and evaluate blade choice such as:

- Feed speed

- Spindle speed

After first article dicing each saw process is typically optimised over time with volume to produce the best quality for a given setup.

For assistance with wafer dicing services please contact sales@diedevices.com

To learn more about post dicing services see bare die pick and placing.

To learn more about pre dicing services see wafer probe testing.