To combat the risk of sub-standard or counterfeit semiconductors entering critical supply chains, tighter purchasing controls are designed to exclude or segregate any bare die products presented without the required certified paperwork.

However, similar to encapsulated (packaged) semiconductors, circumstances arise where there is a need to use bare die which lack some or all of the necessary paperwork. These circumstances arise predominantly due to part scarcity or obsolescence, where the consequential impact of not having parts available means significant economic, strategic and timing impact for the fully assembled product and ultimately delivery of the larger program.

Since encapsulated (packaged) components comprise >99% of all semiconductors supplied globally, there are already a multitude of test steps and standards relating to their assessment. However the bare die format itself is a much more specialist topic with unique considerations and where some of the criteria applied to packaged products do not apply.

The natural result is a hybrid process which combines some of the general criteria applied to packaged components plus specific criteria added for bare die.

A modified AS6081 process provides a basic flow with edits and additional aspects inserted specific to bare die format.

It's important to understand that every situation is different and the sum of factors identified via incoming inspection ultimately dictate a list of additional test steps and sample sizes.

Minimum Inspection

- Documentation - Incoming Paperwork, Packaging & Wafer Jar / Waffle Tray Label Inspection

- Quantify lot homogeneity

- Establish possible age/datecode

- Comparison with official documentation from the same manufacturer via cross-reference with our internal document archive

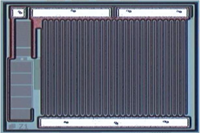

- External Visual Inspection - Die verification and assessment of visual quality

- General

- Catalogue geometry and die markings

- Cross-reference geometry against official die geometry archive

- Dimensional measurement

- Visual assessment of top and back metal (if present)

- Detailed

- 100% visual quality inspection to Mil-Std-883 or Mil-Std-750 as applicable

- General

XRF (non-destructive) or EDS/EDX

Additional Tests (as agreed between Customer and Organization):

- Scanning Electron Microscope

- Quantitative Surface Analysis

- Thermal Cycling Test

- Electrical Testing

- Burn-In (Pre & Post)

- Scanning Acoustic Microscopy (SAM)

That said some of the criteria applied for package components can be applicable depending on the circumstances and bearing in mind that each situation may have different variables: