To combat the risk of sub-standard or counterfeit semiconductors entering critical supply chains, tighter purchasing controls are designed to exclude or segregate any bare die products presented without the required certified paperwork.

However, similar to encapsulated (packaged) semiconductors, circumstances arise where there is a need to use bare die which lack some or all of the necessary paperwork. These circumstances arise predominantly due to part scarcity or obsolescence, where the consequential impact of not having parts available means significant economic, strategic and timing impact for the fully assembled product and ultimately delivery of the larger program.

Since encapsulated (packaged) components comprise >99% of all semiconductors supplied globally, there are already a multitude of test steps and standards relating to their assessment. However the bare die format itself is a much more specialist topic with unique considerations and where some of the criteria applied to packaged products do not apply.

The natural result is a hybrid process which combines some general criteria applied to packaged components with specific criteria added for bare die.

To do that we the AS6081 process with added criteria for bare die

Minimum Inspection:

- Documentation and Packaging

- Documentation and Packaging Inspection

- External Visual Inspection

- General

- Detailed

- Remarking & Resurfacing

- Solvent Test for Remarking

- Solvent Test for Resurfacing

- Radiological (X-Ray) Inspection

- X-Ray Inspection

- Lead Finish Evaluation (XRF or EDS/EDX)

- XRF (non-destructive) or EDS/EDX

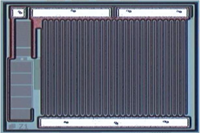

- Delid/Decapsulation Internal Analysis

- Delid/Decapsulation

Additional Tests (as agreed between Customer and Organization):

- Remarking & Resurfacing

- Scanning Electron Microscope

- Quantitative Surface Analysis

- Thermal Cycling Test

- Electrical Testing

- Burn-In (Pre & Post)

- Hermeticity Verification (Fine and Gross Leak)

- Scanning Acoustic Microscopy (SAM)

That said some of the criteria applied for package components can be applicable depending on the circumstances and bearing in mind that each situation may have different variables:

Common variables to consider when creating a bare die validation plan:

- Part type and complexity

- Level of perceived homogeneity via material labels or supporting documents if present

- Perceived age and storage history

- Mechanical make-up

- Mechanical ability for test contacts