K Screening Flow

Sample distribution - Single diffusion, Single Wafer

Sample size - 20 PCS (5 destruct)

Pre-Sample Assembly

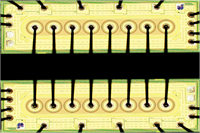

Die Visual Inspection - MIL-STD-750/TM2072, MIL-STD-750/TM2071, MIL-STD-883/TM2010B

SEM Inspection - Scanning Electron Microscopy – MIL-STD-883/TM2018

Sample Assembly

Die Attach - MIL-STD-883/TM2010

Die Shear Test - MIL-STD-883/TM2019

Die Attach Inspection - MIL-STD-883/TM2010

Wire bond – Internal spec

Wire bond integrity - MIL-STD-883/TM2011

Pre-Cap inspection - MIL-STD-883/TM2010

Internal Die Visual - MIL-STD-883/TM2010A, MIL-STD-750/TM2072, MIL-STD-75/TM2073

Package seal - MIL-STD-883/TM1014

Seal Inspection - MIL-STD-883/TM2009

Sample coding – Internal spec

Sample Testing

Stability Bake - MIL-STD-883/TM1008

Temperature Cycle - MIL-STD-883/TM1010

Centrifuge - MIL-STD-883/TM2001

Interim Electrical Test @ 25°C - In accordance with device specification

Interim Electrical Test @ 125°C - In accordance with device specification

Interim Electrical Test @ -55°C - In accordance with device specification

120 hours burn-in @ 150°C - In accordance with device specification

Post 120-hour Electrical Test @ 25°C - In accordance with device specification

Post 120-hour Electrical Test @ 125°C - In accordance with device specification

Post 120-hour Electrical Test @ -55°C - In accordance with device specification

Steady State Life Test @ 150°C – MIL-STD-883/TM1005

Life burn-in 240 hours - MIL-STD-883/TM1015

Final Electrical Test @ 25°C - In accordance with device specification

Final Electrical Test @ 125°C - In accordance with device specification

Final Electrical Test @ -55°C - In accordance with device specification

Outgoing Die Release

From sample tested wafer only

100% die visual inspection - MIL-STD-883/TM2010A, MIL-STD-750/TM2072, MIL-STD-75/TM2073