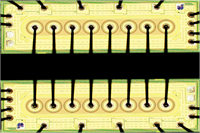

Die Devices is pleased to announce the deployment of additional bare die pick and placing equipment to supplement our existing on-shore capacity.

The addition to our suite of equipment means we can support handling of bare die level components for low volume or specialist applications and high volume placement where timescales and volume quantity outputs matter. All of this is processed within our central UK site and benefits from the quality and experience of our staff who have combined over 40 years experience of handling bare die and similar small size chip level components.

New Equipment Deployment

Automated picking of die sizes from 250µmx250µm (10x10 Mils) to 8.4mmx8.4mm (330x330 Mils)

Featuring:

■ 24-hour operation with high-speed throughput =>5K UPH

■ Integrated in-line inspection filtering out visual defects

■ Integrated in-line inspection filtering out ink dot rejects

■ Integrated electronic map picking from all industry recognized data formats

■ Integrated in-line rotational adjustment ensuring correct die orientation

■ Minimal contact made to the die top surface.

Existing Equipment

Automated picking of die sizes from 200µmx200µm (8x8 Mils) to 25mmx25mm (985x985 Mils)

Featuring:

■ Optional die inversion (die flipping) to prepare bumped bare die for automated assembly

■ Optional in-line backside visual inspection

■ Optional side collection for topside sensitive bare die

■ Integrated in-line inspection filtering out gross visual defects

■ Integrated in-line inspection filtering out ink dot rejects

■ Integrated electronic map picking from most industry recognized data formats.